Just How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Production

The integration of an Optical Fibre Diameter Analyser into Fibre production processes stands for a significant advancement in quality assurance approaches. By providing real-time, specific dimensions of Fibre sizes, this innovation addresses the critical need for uniformity in production standards. With its capacity to swiftly recognize discrepancies and punctual corrective procedures, the analyser not only improves product integrity but likewise adds to general functional efficiency. As markets significantly prioritize high quality and conformity, understanding the full influence of such developments ends up being essential. What ramifications could this have for the future of Fibre manufacturing?

Significance of Fibre Diameter Dimension

Precise measurement of Fibre Diameter is crucial in the field of optical Fibre modern technology, as it straight affects the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capacity, depletion, and total transmission performance. Precision in measuring Fibre Diameter makes sure that the optical homes are kept within defined resistances, which is essential for optimal signal integrity.

Variants in Fibre Diameter can bring about raised losses because of scattering and modal diffusion, influencing the high quality of data transmission. In high-speed interaction systems, such inconsistencies can result in significant destruction of signal high quality, resulting in information mistakes and reduced efficiency. Consistent Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are indispensable components of Fibre optic networks.

Quality control processes in Fibre production greatly depend on exact Diameter dimensions to ensure compliance with sector standards. By applying robust dimension techniques, makers can enhance product integrity, reduce waste, and boost general system efficiency. Thus, the value of Fibre Diameter measurement can not be overemphasized, as it works as a foundation in the advancement of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Works

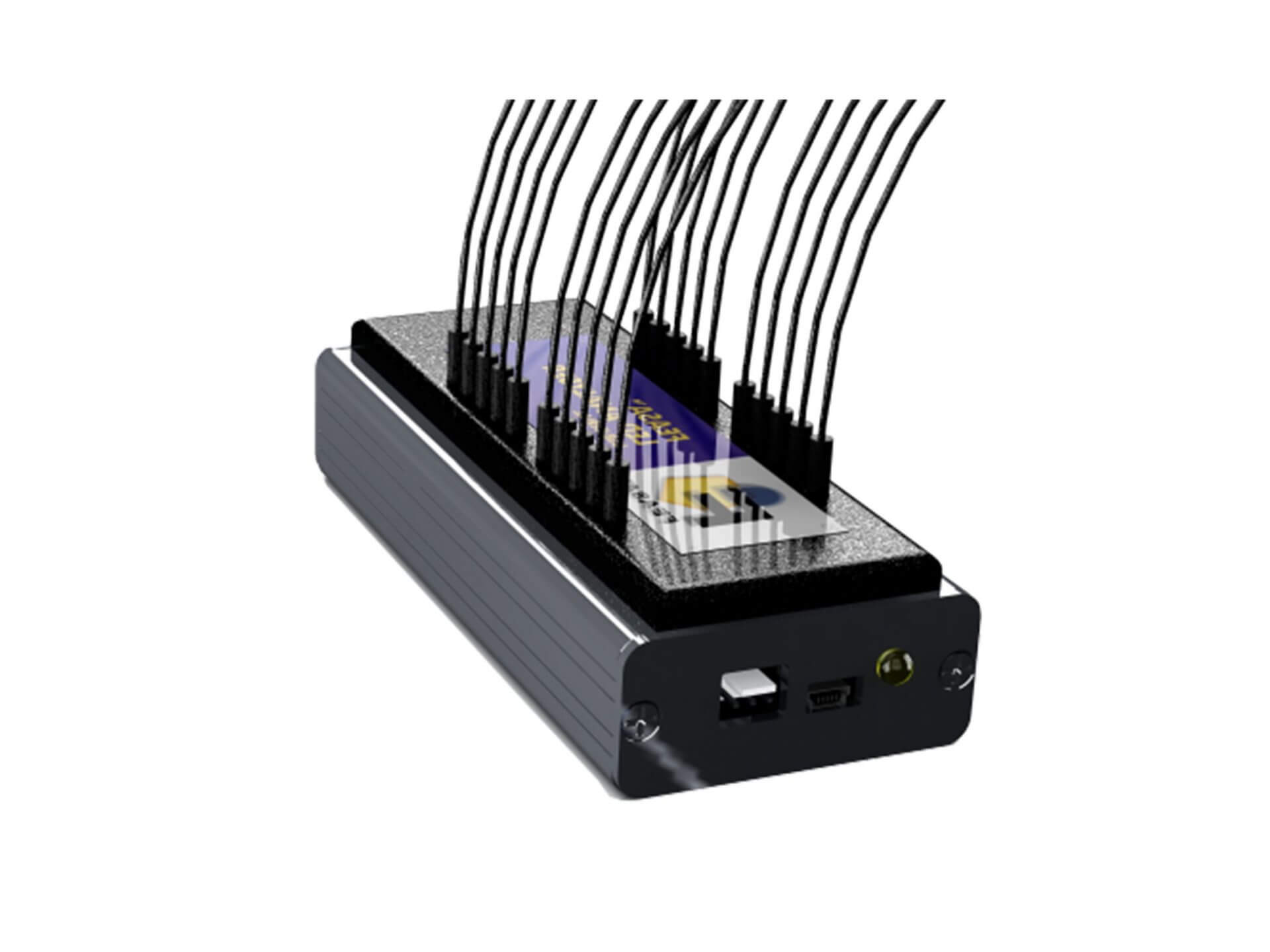

The reliable dimension of Fibre Diameter counts on innovative analytical strategies that guarantee precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser modern technology and advanced image processing formulas to properly analyze the Diameter of fibers as they are created

Originally, a laser beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness making use of high-resolution video cameras positioned tactically along the assembly line. The caught images are then processed in real-time to identify the Fibre's Diameter with exceptional accuracy.

The system uses advanced algorithms that represent various factors, including variations in light intensity and environmental problems, to boost dimension integrity. It can identify minute adjustments in Diameter, such as variations that could happen during the manufacturing process.

Moreover, the analyser can taking care of numerous fibers concurrently, enhancing throughput without compromising precision. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a critical role in keeping stringent quality assurance standards, making sure that the end product satisfies sector specifications and client requirements.

Advantages of Real-Time Monitoring

While traditional techniques of keeping track of Fibre Diameter frequently entail lengthy post-production checks, real-time surveillance substantially improves the effectiveness and quality of optical Fibre production. optical fibre diameter analyser. This positive strategy allows makers to recognize deviations in Fibre Diameter as they happen, as opposed to waiting till production is total to assess high quality

By continuously determining the Diameter throughout manufacturing, manufacturers can guarantee that the fibres satisfy rigorous requirements, leading to reduced variability and boosted uniformity. Real-time basics tracking likewise allows prompt rehabilitative activities to be taken, lessening waste and avoiding defective fibers from going into the supply chain.

Furthermore, this modern technology facilitates enhanced data collection and evaluation, offering insights into manufacturing trends and potential areas for improvement. Such data-driven decision-making encourages suppliers to maximize processes and preserve high standards of quality assurance.

On top of that, real-time tracking promotes a culture of constant improvement within the production environment. Workers are much more engaged when they can see the impact of their operate in real-time, leading to heightened responsibility and a dedication to excellence. Overall, the application of real-time surveillance systems in optical Fibre manufacturing converts to exceptional item quality and enhanced client satisfaction.

Influence On Manufacturing Performance

Executing optical Fibre Diameter analysers dramatically improves production effectiveness by streamlining the manufacturing procedure. These devices assist in continual surveillance of Fibre Diameter, allowing suppliers to discover deviations in real-time. By identifying disparities without delay, assembly line can be adjusted promptly, decreasing downtime and why not try this out lowering the chance of generating defective items.

Furthermore, the assimilation of these analysers into the production workflow makes it possible for better source allocation. With accurate Diameter dimensions, drivers can optimize material use, ensuring that sources are not wasted on flawed fibres. This precision also adds to less revamp and scrap, eventually decreasing production prices.

The automation offered by optical Fibre Diameter analysers minimizes dependence on hands-on examinations, which are prone and usually lengthy to human mistake. Because of this, workers can concentrate on more calculated jobs, enhancing general productivity.

Additionally, the data generated from these analysers can notify procedure improvements and assist in far better decision-making. By analyzing patterns in Fibre Diameter variants, manufacturers can carry out aggressive measures to enhance production methods and keep consistent quality. In recap, optical Fibre Diameter analysers play a critical role in increasing manufacturing performance, leading to higher high quality outcome and boosted productivity.

Study and Success Stories

Across various industries, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One noticeable instance is a leading telecoms firm that dealt with obstacles with irregular Fibre diameters, causing boosted being rejected rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time monitoring of Fibre measurements, causing a 30% decrease in flaws and considerable expense savings.

Additionally, a study organization focusing on advanced products utilized optical Fibre Diameter analysers to refine their speculative procedures. The analyser's ability to give comprehensive understandings right look at here into Fibre uniformity enabled the growth of innovative products with better performance attributes.

These success tales underscore the necessary role of optical Fibre Diameter analysers in boosting quality control, enhancing manufacturing efficiency, and driving development throughout varied industries.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays an essential function in improving quality control within Fibre production. As shown via different situation studies, the analyser proves essential for achieving premium item high quality in Fibre production.

The application of optical Fibre Diameter analysers enabled for rigorous quality control, making certain that the produced fibers met exacting market requirements.In verdict, the Optical Fibre Diameter Analyser plays a crucial role in improving top quality control within Fibre production.